Understanding the benefits of heat treating packaging products is important when choosing wood pallets. Heat-treated wood pallets should comply with the International Standards for Phytosanitary Measures (ISPM-15) requirements. This helps prevent the transfer of harmful pests and insects, which can cause infestation during the exportation process.

Traces of chemical residue from fumigation have led to food and pharmaceutical industry recalls. As a result, heat treatment of shipping pallets has become essential for consumer safety. Currently, fourteen countries (and the entire European Union) have adopted the ISPM-15, which requires debarking, heat treating, and stamping wood pallets with a mark of compliance. All manufacturers and purchasers of wood pallets, crates, and boxes must submit and implement the current standards set by the ISPM-15.

Importance of Heat Treating Wood Pallets

Trees are naturally exposed to fungi, pathogens, and insects via the soil, air, and water. When an infested tree is used to produce pallets, these pests (whether mature or in the larval stage) can be transported to another country and put its native plant life at risk. (In Canada alone, the Asian beetle and the ash borer have been known to devastate large populations of healthy trees). To prevent these and other pests from spreading, governments, environmentalists, and manufacturers developed a new approach to pallet production and began to incorporate heat treatment.

The Heat Treatment Process

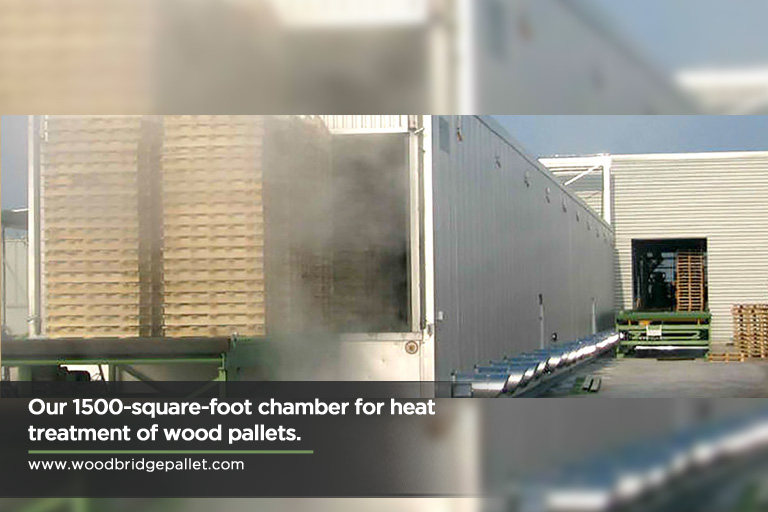

There are various ways to treat lumber with heat, and some are more efficient than others. The method used depends upon the end user application. To comply with ISPM-15, wood must be heated until the core temperature reaches 56 degrees Celsius for at least 30 minutes. During the heat treatment process, wood is placed in a special chamber. Some processes involve subjecting it to heat and moisture over several hours. Others use low, dry heat over a several days (kiln drying). In Canada, softwood lumber is processed and dried in kilns with a moisture content of 9 to 20 percent.

Once ready for shipment, heat treated pallets are then stamped with an internationally recognized mark of proof certifying that the ISPM-15 standards have been met and that the packaging has no wood-borne pests or insects.

Benefits of Heating Pallets

ISPM-15 is strictly enforced to reduce the risk of infestation. When foreign insects and other pests spread across borders, both the environment and population are put at risk. Infestation can also directly expose pallet handlers to illness and disease.

Heat treating wood is beneficial for several reasons:

- Environmentally Friendly – Unlike toxic methods that use methyl bromide to disinfect wood, no harmful chemicals are used during the heat treating process. This protects the environment and allows old and damaged pallets to be recycled as wood chips and repurposed.

- Adds Longevity and Quality – When wood is heat treated, its composition changes. It becomes more resistant to micro-organisms like fungi that can cause it to rot, despite exposure to moisture and extreme humidity. Heat also increases its longevity by hardening it and making it less permeable and susceptible to decay. When cared for properly, heat treated wood will not warp, crack, or chip and can last for decades, making it ideal for use in shipping. Heating wood also reduces the risk of swelling and shrinkage.

- Lighter in Weight – Heat treatment destroys sap, reduces the overall moisture content, and makes the wood more resistant to water absorption. It can also save you money on shipping costs because the wood is more lightweight.

- Accepted Internationally – Wood pallets used in cross-border shipments must strictly adhere to ISPM-15. Using heat treated pallets allows for easier and more compliant transport across international boundaries.

Documentation and Standards

Wood pallets that meet the ISPM-15 standards are imprinted with the International Plant Protection Convention logo (the letters “IPPC” beside an ear of corn), as well as a two-letter International Standards Organization country code. This code is necessary for tracking the country responsible for the wood’s passage into the supply chain. Other information includes the regulator in charge of the heat treating process and the certification number of the pallet manufacturer. Two letters signifying the treatment method are also put on pallets: “HT” means the wood was heat treated; “MB” refers to a fumigation process using methyl bromide.

While other manufacturers add extra details on heat treated pallets, the ISPM-15 authentication mark is enough to show that they’re safe to use for cross-border shipments. Failure to adhere to the requirements will prevent entry into most countries, making it important to purchase pallets from a reputable company. Look for these essential logos when you use wood pallets to ship goods internationally or domestically.

ISPM-15 in Canada and the USA

As members of the IPPC, both Canada and the USA have adopted ISPM-15 regulations. All shipments of wood packing materials, whether domestic or international, must be treated and stamped with the IPPC mark. Shipments directly between Canada and the US are exempt from ISPM-15 requirements. However, the rules for international shipping from Canada or the US to other countries must be followed.

Despite the ISPM-15 exemption between Canada and the US, a proposed amendment removing the exemption is currently under review. Since December 2010, the countries have been looking into regulating WPMs shipped across their borders. While the decision to enforce ISPM-15 standards has been reached, a date for full implementation has not yet been established. Once the regulations are put forth, WPMs that fail to meet the standards will be prohibited from entering either country. If pests are detected upon arrival, wood pallets will have to be treated again before their return to the country of origin. The carrier of the shipment will be responsible for all costs incurred.

Woodbridge Pallet Ltd. has a 1500-square-foot chamber for heat treatment to certify new and used wood pallets and other WPMs. Our years of experience in the wood pallet business assure compliance with ISPM-15 requirements. Customer satisfaction is our highest priority, so for design, repair, and other wood pallet services in Toronto, call us at (905) 856-3332.